Enormous efficiency gains with ETAS INCA-FLOW accelerating E-Drive innovation

#CustomerSuccessStory

A leading Chinese OEM, operating at the forefront of China's "Dual Carbon" strategy and new energy vehicle evolution, faced mounting pressure to accelerate e-drive system development while maintaining superior motor performance. As market demands for electric motor efficiency intensified and iteration cycles shortened dramatically, their R&D team partnered with ETAS to implement an automated motor calibration solution. The goal was to transform their development capabilities and deliver breakthrough efficiency gains in their electric vehicle portfolio.

The challenge

The customer's engineering teams were trapped in intensive, manual motor calibration processes that threatened their competitive position in China's rapidly evolving EV market. Traditional calibration methods relied on individual engineer expertise, with manual testing, recording, and parameter adjustments consuming weeks per motor project. Human errors created inconsistent test data, undermining calibration accuracy and reliability. The dependency on scarce, high-cost senior engineers created scaling bottlenecks, while time and cost constraints prevented comprehensive parameter exploration, potentially leaving critical motor performance gains undiscovered.

The solution

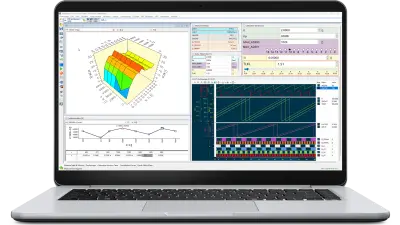

ETAS deployed its automated calibration solution, INCA-FLOW, integrating seamlessly with the customer's existing INCA toolchain. The implementation included 24/7 automated test case execution and sophisticated algorithms that automatically identified optimal parameter combinations, significantly reducing trial runs. The solution standardized calibration processes by embedding expert knowledge into repeatable workflows, ensuring consistent, high-quality results across all engineers and projects. ETAS provided dedicated local technical support throughout deployment, while the platform's data management capabilities automatically collected and preprocessed large test data volumes, generating visual reports for rapid decision-making.

Customer achievements

The transformation delivered exceptional improvements across all critical metrics. Motor calibration time dropped from four weeks to just one week per project, representing a remarkable 75% efficiency increase that accelerated time-to-market enormously. The customer also achieved substantial cost reductions through optimized bench occupancy and reduced labor requirements. Calibration consistency improved tremendously, ensuring mass-production quality standards.

Most notably, global parameter optimization enhanced motor peak efficiency by 1% on identical hardware, directly improving vehicle range performance. Beyond its remarkable impact on these key tasks, the new tool represented a significant improvement for the team. Senior engineers were liberated from repetitive tasks, enabling focus on cutting-edge research and core technology development.

Conclusion/Future Outlook

This success story shows ETAS's capability to deliver transformational efficiency gains while enhancing technical performance for automotive industry leaders. The customer has expanded INCA-FLOW adoption across motor bench calibration projects and plans full automation of all motor calibration processes within one year. As INCA-FLOW becomes the preferred solution for leading companies in China's new energy sector, this partnership demonstrates ETAS's commitment to providing cutting-edge solutions that accelerate innovation and further competitive advantages. The strategic relationship positions both companies to continue pushing e-drive system development boundaries in the world's largest automotive market.

Contact us

Do you have any questions? Feel free to send us a message. We will be more than happy to help. Contact us today!