From challenge to launch: How our customer mastered EV calibration with ETAS INCA

#CustomerSuccessStory

The customer, a renowned sports car manufacturer faced a strategic challenge: developing their first series production electric vehicle while maintaining legendary performance standards. As the industry shifted toward electrification, they needed to master electric drivetrain calibration and energy management while establishing scalable processes for future Electric Vehicles (EV). ETAS's INCA platform and ETK solutions enabled them to successfully navigate EV calibration complexities and bring their electric vehicle program from concept to production readiness.

At a glance

Challenge:

Mastering complex EV calibration (energy management, regenerative braking, battery optimization) while establishing future-proof,

efficient calibration processes and accelerating development.

Solution:

Deployment of the ETAS INCA platform with ETK modules for real-time parameter capture,

specialized experiment templates, and automated calibration processes.

Customer achievement:

Significant increase in data quality and validation confidence, range optimization without costly hardware changes, establishment of a scalable EV portfolio and "100% partnership satisfaction"

The challenge

The customer's transition to electric mobility introduced new complexities that required different approaches to address them effectively. Electric drivetrains required precise real-time calibration of energy management, regenerative braking, and battery optimization. Safety-critical functions needed extensive validation to prevent hazards and ensure reliability. Efficiency optimization became crucial. With compressed development cycles and multiple EV variants planned, the customer's teams faced parameter adjustment and validation bottlenecks that threatened market entry timelines.

The solution

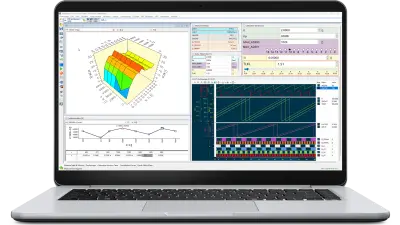

ETAS deployed their INCA platform with ETK modules to transform the customer´s calibration approach. Real-time parameter capture enabled precise control unit adjustments during live testing with exceptional accuracy. Specialized experiment templates streamlined battery instrumentation and energy management validation. Automated processes eliminated manual intervention, accelerating development cycles while maintaining precision across electric drivetrain, energy management, and safety systems.

Customer achievement

INCA implementation delivered transformative improvements across then customer's EV program. Enhanced data quality boosted validation confidence and regulatory compliance. Fine-tuned drivetrain calibration preserved the brand's signature dynamics. Safety-critical functions were strengthened, addressing battery hazard concerns while extending battery life through optimized management.

Most significantly, the project achieved increased vehicle range through better system utilization instead of via costly hardware changes. Also, overall system reliability improved via elevated safety standards. These improvements established a solid foundation for the customer's electric vehicle production while creating a scalable framework for his expanding EV portfolio.

Conclusion

This collaboration successfully established the customer's foundation for electric vehicle series production while demonstrating ETAS INCA's effectiveness in managing complex EV calibration challenges.

The partnership highlights how specialized calibration tools can accelerate automotive electrification while maintaining the highest standards for safety, performance, and reliability that define high reputation of automotive brands.

Contact us

Do you have any questions? Feel free to send us a message. We will be more than happy to help. Contact us today!