INCA: Precision development & calibration for electric mobility excellence

ETAS INCA empowers you to master every aspect of electric vehicle development, from battery management to e-motor control, with unmatched efficiency and insight.

INCA:The integrated platform to handle EV complexity from simulation to series

INCA is more than just a tool; it's an integrated ecosystem designed to handle the intricate demands of electric vehicle development. We've translated our decades of expertise from optimizing conventional engine systems to mastering the unique challenges of electric motion, ensuring continuity and reliability in your workflows.

Accelerate development

Reduce engineering effort and shorten development cycles by balancing key parameters like range, charging, and performance faster.

Optimize energy performance

Maximize battery utilization and energy efficiency through comprehensive system-wide calibration and synchronized multi-ECU measurement across all EV operating conditions for peak propulsion performance.

Master transition easily

Leverage proven automotive calibration methodologies and familiar INCA workflows to transition seamlessly from ICE to EV development without costly tool changes or extensive retraining requirements.

Ensure system reliability

Validate critical EV performance through comprehensive battery cell monitoring, charging compatibility testing, and real-time safety parameter validation that prevents component failures and ensures regulatory compliance.

Faster Validation

Shorten development cycles through direct ECU access for accelerated troubleshooting and validation.

Master complexity

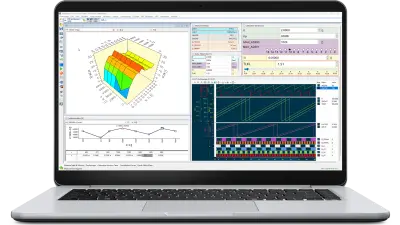

Identify critical data points faster in complex EV systems by integrating advanced calculation engines and visualisation tools.

Products for EV calibration

- INCA/MDA: EV Battery Instruments page

- MDA: Battery Calculations

- INCA-FLOW: Calibration process automation

- ASCMO: AI based data analysis and model generation

- ASCMO-MOCA: Creation of calibration data from Models

- EHANDBOOK: Interactive documentation solution

- ETK: High performance ECU access

- Network devices: Automotive bus access

EV Calibration with INCA and Integration of 3rd party devices

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

Advanced features for electric vehicle optimization

Our solutions provide the deep access and analytical power required for cutting-edge electric vehicle development:

The battery defines the most crucial vehicle parameters (range, power, weight) of an EV and is the most expensive component. During vehicle operation, the battery Management System (BMS) monitors each cell and controls the operation of the battery.

Utilize specialized instruments in INCA and MDA to visualize individual battery cell voltages, identify outliers, and optimize balancing strategies for extended battery life and usable capacity.

Energy storage capability of EV batteries is limited and very costly. One of the main development goals is maximizing the range of the vehicle. Thus, efficiency is the main driver in the vehicle development. Acquire voltage and current applied to the electric motor with specialized measurement devices from Dewesoft, Hioki or Yokogawa and utilize sophisticated instruments and calculations in MDA for detailed analysis and efficiency optimization.

Leverage the specialized calculation library which addresses unique EV development challenges with pre-built functions that encapsulate deep automotive engineering expertise.

Support of arrays makes the handling of multi signal sources like BMS simple and efficient.

Acquire signals from the thermal system from various ECU & sensors, and utilize

specific calculations in MDA for detailed analysis of flow and accumulation of thermal energy.

Access all vehicle control systems with support for up to 100,000+ measurement labels and microsecond-precision timing for real-time, microcontroller-independent data acquisition and holistic development workflows.

Rapidly visualize and analyze massive automotive measurement datasets with MDA, accelerating validation processes and quickly identifying critical data points in complex electric vehicle systems.

Streamline complex calibration tasks and reduce manual effort with guided workflows, ensuring reproducible and consistent results across vehicle, test-bench, and simulation environments.

Efficiently validate, calibrate, and test ECUs across traditional and modern vehicle networks with robust hardware solutions offering universal protocol support and scalable architectures, adapting to your project's complexity from prototype to production.

Your local team, always within reach

Our dedicated regional specialists are strategically positioned to be right where you are. We bring global expertise directly to your site, ensuring rapid issue resolution and empowering you to outpace the market.