Empowering tomorrow’s

automotive software

At ETAS, we empower automotive OEMs and suppliers to shape the future of mobility. By streamlining the development of software-defined vehicles, we help you manage software complexity, accelerate development cycles, and ensure safety and security compliance.

ETAS - your partner for the future mobility

At ETAS, we help you with the questions that matter. How do you ensure smooth, reliable software integration with automotive middleware? How can you improve the efficiency of your electric powertrains? How can you successfully integrate free and open source software and meet cybersecurity requirements? We help you address the issues that are shaping the present and future of the automotive industry.

About ETAS

1994

Foundation as subsidiary of Robert Bosch GmbH

3.000

Associates approx.

42 locations in 13 countries

Global presence

599 million euros

Sales in 2024

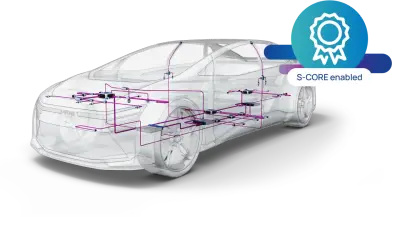

Shift your software delivery performance into a higher gear

As we move toward the software-defined vehicle, automotive applications need to be developed much faster and deployed at scale. Vast amounts of data must be collected and analyzed to inform data-driven development of vehicle functions. To keep pace, you need to integrate development and test toolchains and establish an efficient DevOps process through standardized base software, middleware, and configuration tools – all while maintaining safety and security.

We at ETAS help you to achieve this with our expertise, solutions and services