ES910

ES910 – Prototyping and interface module

The ES910 prototyping and interface module combines high computing performance with all common ECU interfaces in a compact and robust housing. It is designed for use in the development environment as well as in standalone operation.

CAN and LIN interfaces ensure the connection of the ES910 module to vehicle buses. Both CAN interfaces support High Speed and Low Speed CAN and can be individually configured. With the help of ETK, XETK, and CAN interfaces, sub-applications can be simulated on the ES910 module and synchronized with a development ECU (rapid prototyping bypass experiment). The proprietary ETK interface meets high real-time requirements, while XETK and CAN support the open XCP protocol for bypass purposes.

The core of the module consists of an NXP PowerQUICC™ processor with double-precision floating-point arithmetic that perfectly suits rapid prototyping applications. The microprocessor characteristics, the RTA-OSEK real-time operating system, and the inbuilt non-volatile RAM (NVRAM) enable simulations with system-level behavior.

The INTECRIO and ASCET-RP (Rapid Prototyping) prototyping tools enable easy configuration of the ES910 module. During the INTECRIO experiment, the user has access to the model, which is run by the ES910 module.T

he INCA-EIP (Experimental Target Integration Package) add-on provides access to the parameters of the design models on the ES910 module in INCA. From the perspective of INCA, the pre-configured ES910 module behaves in the same way as an ECU with measurement and calibration access. The ETK, XETK, CAN, and LIN interfaces of the ES910 module can also be used with INCA to collect data or for ECU calibration.

The ES910 module works in combination with the INCA-MCE (Measurement and Calibration Embedded) application on the test bench to ensure the quick exchange of measurement and calibration data between ECU and test bench automation.

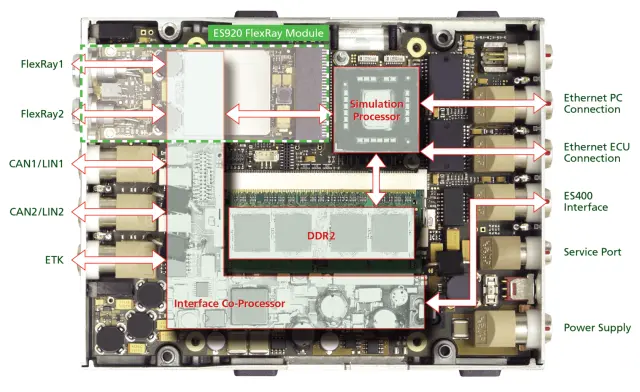

If required, the ES910 basis module can be extended using either a FlexRay node with two channels (ES920) or two CAN or CAN FD interfaces (ES921 or ES922).

Your benefits

- Compact prototyping and interface module for function development and ECU calibration

- PowerQUICCTM III MPC8548 processor for real-time calculations

- ETK, XETK, CAN, and LIN interfaces

- Flexibly expandable with additional FlexRay, CAN, or CAN FD interface modules ES920 / ES921 / ES922

- Integrated into INCA, INTECRIO, and ASCET-RP

- Supported by ETK, XETK, XCP-on-Ethernet, and XCP-on-CAN bypass

- Interconnection of ES400 and ES63x measurement modules possible

- Supports EtherCAT® und iLinkRT™ test bench automation interfaces ( INCA-MCE )

- Standalone operation possible

Vehicle and Test Bench Application

ETAS INCA/INCA-EIP (Experimental Target Integration Package) provides for direct calibration of the prototypes of new control algorithms on the ES910 module. In addition, the ES910 module can be used by INCA for calibration, acquisition of ECU and bus signals, flash programming and diagnostics (CAN).

The automated calibration on the test bench is supported by the ES910 module as a custom solution: In conjunction with the ETAS INCA-MCE Engineering Solution (Measurement and Calibration Embedded), the ES910 module provides for fast exchange of measurement and calibration values between ECU and test bench automation. The ES910 module converts and transfers data between ECU and test bench. Communication between test bench automation and the ES910 module takes place in real time using the EtherCAT® or iLinkRT™ protocols. The ES910 module allows you to realize measurement and calibration applications with very short cycle times.

Technical Data

| Size and Weight | |

|

Size and Weight

Dimensions (HxWxD)

|

36 x 127 x 160 mm / 1.4 x 5 x 6.3 in

|

|

Size and Weight

Weight

|

Approx. 850 g / 1.87 lb

|

|

Size and Weight

Environment

|

|

|

Size and Weight

Temperature range

|

-40 °C to +50 °C / -40 °F to +122 °F (operation)

|

|

Size and Weight

|

-40 °C to +85 °C / -40 °F to +185 °F (storage)

|

|

Size and Weight

Power supply

|

|

|

Size and Weight

Input voltage

|

6 V to 32 V DC

|

|

Size and Weight

Power consumption

|

14 W (typically) / 20 W (max.)

|

|

Size and Weight

Stand-by current

|

< 25 mA

|

|

Size and Weight

Host interface

|

|

|

Size and Weight

Ethernet connection

|

10/100/1000 Base-T

|

|

Size and Weight

Protocol

|

TCP/IP

|

|

Size and Weight

IP address

|

Dynamic

|

|

Size and Weight

Simulation target

|

|

|

Size and Weight

Main processor

|

NXP PowerQUICC™ III MPC8548 with 800 MHz clock Double precision floating point unit

|

|

Size and Weight

Memory

|

|

|

Size and Weight

RAM

|

512 MByte DDR2-RAM (400 MHz clock)

|

|

Size and Weight

Flash

|

64 MByte Flash

|

|

Size and Weight

NVRAM

|

128 kByte NVRAM

|

|

Size and Weight

ECU and bus interfaces

|

|

|

Size and Weight

ETK

|

1 Channel, ETK Mode: Basic, Compatibility, Advanced

ETK bypass method: hook based or service based (Service Based Bypass (SBB V2) and SBB V3 [1]) |

|

Size and Weight

ECU

|

1 channel

Operation Modes: XETK interface, iLinkRT Bypass methods: SBB V2 Application: Measurement, calibration and bypass with XETK, Test bench connection via iLintRT™ using INCA-MCE [2] |

|

Size and Weight

CAN

|

2 Channels, High Speed (up to 1 MBaud) or Low Speed

|

|

Size and Weight

LIN

|

2 Channels, LIN V2.2A

|

|

Size and Weight

Other interfaces

|

|

|

Size and Weight

Extension modules

|

ES920 FlexRay Module (1 Node with 2 channels) or ES921 CAN Module (2 CAN channels) or ES922 CAN FD Module (2 CAN FD channels)

|

|

Size and Weight

I/O: ES400 / EtherCAT interface

|

Connection of ES400 Micro Measurement Modules and ES63x Lambda Modules for rapid prototyping applications

|

|

Size and Weight

|

EtherCAT connection to test bench for INCA-MCE[3]

|

|

Size and Weight

Wake-up

|

|

|

Size and Weight

SP: service port

|

wake-up control input, manual trigger input for security functions such as emergency stop and shutdown scenarios

|

|

Size and Weight

PC

|

Wake-up over Ethernet interface

|

|

Size and Weight

CAN

|

Wake-up over CAN

|

|

Size and Weight

Safety and comfort features

|

|

|

Size and Weight

|

Wake-up control input of service port

|

|

Size and Weight

Operating system

|

Advanced user watchdog

|

|

Size and Weight

LEDs

|

For quick status check

|

|

Size and Weight

User LEDs

|

User programmable

|

|

Size and Weight

Buzzer

|

User programmable

|

|

Size and Weight

Buffered realtime clock

|

Buffer period: 2 days (min.), 1 week at +25 °C / +77 °F (typically)

|

|

Size and Weight

Support by ETAS Software [5]

|

|

|

Size and Weight

|

INTECRIO, ASCET-RP, INCA, INCA-EIP, ODX-LINK/ODX-FLASH (Diagnosis and Flash-Programming via CAN), INCA-MCE with INCA [4], RTA-TRACE, HSP

|

[1] SBB V3 with INTECRIO V4.0, HSP V9.4; for ES910.3 only (not for ES910.2)

[2] iLinkRT™ with INCA V7.0, INCA-MCE V1.0, HSP V9.4; for ES910.3 only (not for ES910.2)

[3] EtherCAT with INCA V7.0, INCA-MCE V1.0, HSP V9.4; for ES910.3 only (not for ES910.2)

[4] INCA-MCE V1.0 requires INCA V7.0, HSP V9.4.0, for ES910.3 only (not for ES910.2)

[5] Please contact your local ETAS representative to request the compatible versions.

This product has been developed and released for use in automotive applications. For usage in other domains please contact your ETAS representative.

Contact us

Do you have any questions? Feel free to send us a message. We will be more than happy to help. Contact us today!